Machine Parts

Hard Chrome Plated Bearings

Profile Cut Arms

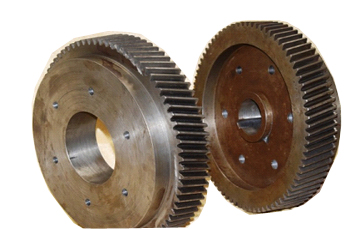

All Steel Gears

Hardened and ground finished Impression Plate (make ready plate)

Auto Timmed Motorise Lub Pump

Heat Treated ‘S’ Cam

Surface Level by Scrapping Method

Address:

M.I.D.C. PLOT NO. 7, Phase-1, Near State Bank, Dombivli - 421 203. Dist Thane (Maharashtra) INDIA